Intro

A friend of mine had complained about loosing those silly little caps from his Nissin callipers and then faced the issue of not having them fitted ie. seized calliper pins.

Design

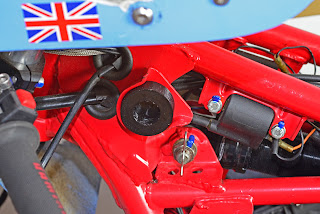

A quick potter about the workshops looking for a loose calliper and I found the part I wanted on the NSR250 MC28 as I popped in for a brew.

A short while later I had it measured as an M10/1mm and 15 minutes later I had finished my brew and the printer was making some noise. I could have had them done quicker but first time round I wanted to add the dimple in the middle of the slot which I quickly binned to add strength.

I made them long at first to add some meat but was the over hang just makes them look loose so I cut them a bit shorter.

With the length about right I was basically done. Printing in CF PETg for heat dissipation, I changed to PETg as I didn't want to cause difference metal corrosion (yes carbon is in that chart). This however was a bit soft for my liking so went with ASA. Thankfully the Galaxy black I have is a near perfect match for the black powder coat.

I knew these would be a bugger for cross threading as the standard steel covers are bad enough but these were far worse than I would have liked.

I figured out I had not cut the thread through the bottom chamfer which was binding up the thread making the part twist. Fixing this and printing upside down got me to a pretty damn good part. Amazing how much faff you can have when you are unsatisfied with just okay from what is, in itself, a compromise part.

|

| Looking good. |

Comments

Post a Comment