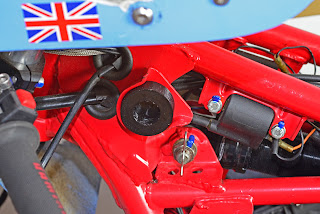

CBX1000 plastic parts

Everyone's favourite 6 cylinder motorcycle is getting some attention. We have developed a version of Honda's screw cap part number 64109MA2000 which fits on the front fairing leg screws. These often wear and fall off so we made them fit a little tighter and managed to keep the cost right down whilst we were at it. Make sure they are nice and warm before fitting as they are a small part and liable to split along the layer lines during fitting. These caps fit the following classic Hondas: CBX400F2 C Euro 82, CBX550F2 C & D 82-83, CBX1000 B & C 81-82, CB750F C 82 CB750F2 C & D 82-83, CB900F B & C 81-82, CB900F2 BOL D'OR B & C, You can buy yours here